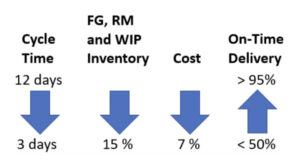

“A nice bonus was discovering that we also got a 7 percent cost savings, because there was less confusion in the process.”

“A nice bonus was discovering that we also got a 7 percent cost savings, because there was less confusion in the process.”

Customers demanded price reductions as material prices were rising. Had already started Lean and setup reduction, problem was not getting resolved quickly enough.

Trained employees in practical operations science of Factory Physics concepts. Employees applied concepts to make changes. Modeled operations layout scenarios using CSUITE Operations Analytics software. This enabled quick determination of best changes. Used CSUITE Inventory Optimizer to determine best possible inventory levels and control policies, prioritized and quantified LEAN efforts.

The results on the right show the benefits gained by Moog from the engagement. The cost reduction was not the immediate goal but a welcome benefit. Moog used the inventory optimization analysis to pinpoint best places for setup reduction—too often companies take the shotgun approach. Moog has continued to apply Factory Physics concepts and training for further gains throughout the company.

Industrial Controls Division of Moog, Inc. designs and manufactures a variety of products for industrial applications including precision control valves, hydraulic manifold systems and electric motors and drives.

They were having significant problems meeting customer market lead times and losing market share to their competitors. Worked with Factory Physics Inc. to redesign operations layout and optimize inventory.