At Factory Physics Inc., I have railed against buzzword initiatives for years. Buzzword initiatives are akin to death and taxes—not anything people like but they seem to be unavoidable. Companies continually launch buzzword initiatives like rock concerts, e.g. Lean, SixSigma, Lean SixSigma, Theory of Constraints, Big Data, DDMRP, AI, and Blockchain to name a few. Note the early adopter in the picture above who has already climbed on someone’s shoulders to express hardy support for the latest initiative being launched. (Photo is by Yvette de Wit on Unsplash) So I am now in favor of buzzword initiatives? Well, yes, with qualifications.

Turns out that buzzword initiatives have good qualities and the operations science described in Factory Physics for Managers and Factory Physics provides critical knowledge for ensuring and sustaining success. This operations science is objective knowledge that you can apply now to boost your management efforts.

How did I rehabilitate my understanding of buzzword initiatives? I applied a simple hypothesis test. A few decades ago my hypothesis was that buzzword initiatives were generally light-weight in content and not very helpful or inspirational. Therefore, companies would discontinue them. A few decades’ experience later it has become obvious that buzzword initiatives are not going away—OK, I’m slow but I can be trained. I’ve heard some good reasons supporting buzzword initiatives:

These are all true and provide a good explanation of why management initiatives are not going away. The problem is that many management initiatives are not successful in improving performance. Additionally, successful management initiatives are generally not sustainable and tend to fade away. Some of that is due to market changes or the migration of leaders and key personnel. However, a deeper look at the way the brain works provides powerful ideas for improving and successfully sustaining initiatives.

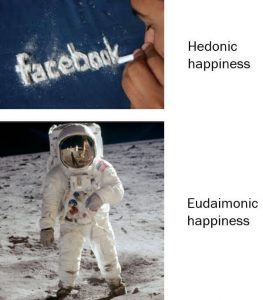

There’s an interesting article in Forbes (click here for the article) describing The Happiness Hack, a book by Ellen Leanse. Management initiatives are not designed specifically to make employees happy but the ideas Ms. Leanse describes can help ensure initiatives are more successful more of the time. To start, human reward cycles are associated with a fast reward dopamine cycle (“hedonic” happiness):

And a slower reward cycle associated with serotonin (“eudaimonic” happiness):

It’s fairly obvious that, as a culture, we’ve been hacked by the fast reward cycle. Management should not expect that banners, coffee cups, rallies and social media campaigns supporting initiatives will actually sustain initiatives. Some companies use repeated annual initiatives primarily for rallying the troops. Often there’s no real substance to these initiatives. They fall into the hedonic happiness category causing burnout and cynicism. A better approach is to structure initiatives to activate serotonin and create better quality and sustainability of results.

The second idea is that fear is a natural response to change. This is no surprise for those familiar with change management. Change inspires resistance because, unless there’s a burning platform, the brain thinks, “Hey, I’m alive, been making it fine as things are.” Any new initiative must take explicit action to address and overcome that fear.

The third idea is that “What got you here won’t get you there.” As we like to say at FPI, “Your company is optimally designed to get the performance you are getting now.” If you want different performance you need to change the design of your company and its processes. This is a different idea. Treat your company, its processes and resources (people and equipment) as a design initiative and apply all attendant science governing good design.

In a perfect world, demand and supply are exactly aligned and there’s no variability. All demand is met instantly at minimum cost—100% on-time at minimum cost which yields maximum profit and cash flow. We don’t live in a perfect world. There is variability in the real world and companies WILL use some combination of inventory, capacity and time to buffer that variability when trying to meet demand. Many companies do not have a good understanding of the relationships between inventory, capacity, response time and variability so their performance suffers.

The Forbes article describes three of Ms. Leanse’s ideas to successfully work with neuroscience to improve work. I’ll add the dimension of practical operations science to her ideas. The combination provides powerful actions for improving and sustaining your management initiatives’ success.

What has worked well with your company’s initiatives? What has not worked so well?

Contact Factory Physics Inc. to find out how to quickly address your company’s inventory, cost, service or lead time challenges.

Ed Pound is Chief Operations Officer of Factory Physics Inc. Ed has worked with major international companies such as Intel, Chevron, 3M, Baxter Healthcare and Whirlpool providing education and consulting in practical operations science concepts. Ed’s work has helped companies realize millions of dollars in improvements and make operations, supply chain management, capital project delivery and product development easier. Ed is lead author, along with Dr. Mark Spearman and Jeff Bell, of McGraw-Hill’s lead business title Factory Physics for Managers.

Ed Pound is Chief Operations Officer of Factory Physics Inc. Ed has worked with major international companies such as Intel, Chevron, 3M, Baxter Healthcare and Whirlpool providing education and consulting in practical operations science concepts. Ed’s work has helped companies realize millions of dollars in improvements and make operations, supply chain management, capital project delivery and product development easier. Ed is lead author, along with Dr. Mark Spearman and Jeff Bell, of McGraw-Hill’s lead business title Factory Physics for Managers.

For more information on operations science, CSUITE Operations Analytics and Factory Physics services, send an email to Ed at espound@factoryphysics.com